Boilers, or steam generators, are one of the most common types of industrial equipment we come across in the field. We’ve seen boilers in numerous settings, including:

- Petroleum refining

- Commercial baking

- Pharmaceutical manufacturing

- Dairies

- Wire drawing

Within the South Coast Air Quality Mangement District (SCAQMD), boilers are subject to numerous regulations, which, of course, means they also come with their very own set of problems. At the end of the article, I’ll share the single most important thing we learned by helping our clients operate a successful boiler-compliance program within the SCAQMD.

But first, the basics.

What Are the SCAQMD Rules for Boilers?

Most units that operate within the SCAQMD are subject to one of two rules:

Each of these rules has specific emission limits and strict maintenance and monitoring requirements.

General Requirements for SCAQMD Rules 1146 and 1146.1

Rule 1146.1 covers units that have a rated heat input of 2-5 MMBTU/hr., while Rule 1146 covers larger boilers that have a rated heat input of >5 MMBTU/hr.

While there are differences between Rule 1146 and 1146.1, a facility subject to these rules can generally expect:

- A 9 PPM emissions limit for oxides of nitrogen (NOx)

- Source Testing requirements

- Periodic NOX and carbon monoxide (CO) emission checks with a portable emissions analyzer

- Certain requirements to install continuous emissions monitoring systems (CEMS)

SCAQMD Emission Limits for boilers

For new units that are subject to both Rule 1146 and 1146.1, these units must meet the following oxides of nitrogen (NOx) and carbon monoxide (CO) limits:

- NOX: 9 PPM @ 3% O2

- CO: 400 PPM @ 3 % O2

Most boiler manufacturers will provide an emissions guarantee that the boiler will meet these emission limits.

During the SCAQMD permitting process, you will likely need to provide a new source review and an emissions guarantee to your permit engineer to demonstrate compliance with Rule 1146 or Rule 1146.1.

Source-Testing Requirements

Source, or emission, testing to demonstrate compliance with the NOx and CO emission limits is required under both Rule 1146 and Rule 1146.1.

The frequency of the source test is dependent on the size of the unit.

For example, testing for units that are equal to or greater than 10 MMBTU/hr is required every three years.

Testing for units that have a rated heat input of less than 10 MMBTU/hr but an input greater than 2 MMBTU/hr is required every five years.

In both cases, the source tests must be completed at least 250 operating hours or 30 days after a tuning or servicing of the unit, unless the service was due to an unscheduled repair.

It’s important to note that the required source tests must be completed by an approved SCAQMD testing firm.

Emission Testing Using a Portable Analyzer

Both Rules 1146 and 1146.1 require the periodic testing of NOx and CO using a portable analyzer.

A portable analyzer is a handheld analyzer that measures the NOx and CO from the boiler while it is in operation.

Similar to the source testing requirements, the frequency of the portable analyzer testing is dependent on the size of the units.

SCAQMD 1146 portable analyzer testing frequency

For units covered by Rule 1146, portable analyzer testing is required once a month or every 750 unit operating hours.

The testing frequency can be extended to quarterly or every 2,000 operating hours if the unit is in compliance for three consecutive emission checks without any adjustments to the oxygen set points. This is called the extended frequency schedule.

In the case of a failed portable analyzer test, the testing schedule reverts to every 750 unit operating hours.

SCAQMD 1146.1 portable analyzer testing frequency

For units covered by Rule 1146.1, portable analyzer testing is required every 2,000 unit operating hours.

If a unit passes four consecutive portable analyzer tests without any adjustments to the oxygen set points, the unit may then be checked semi-annually or every 4,000 unit operating hours until it fails a portable analyzer test.

In the case of a failed portable analyzer test, the testing schedule reverts to every 2,000 unit operating hours.

If a unit fails an emissions test while on the extended testing frequency, the boiler must start at the more frequent testing schedule until it passes the minimum number of tests for the frequency to be extended.

Portable Analyzer Tests Must Be Conducted by an SCAQMD-Certified Technician

These portable analyzer tests must be performed by a technician who has received a certification from the SCAQMD.

Records of all portable analyzer tests must be kept for at least two years.

Records must be kept for five years if the facility is subject to Title V.

Requirements for Continuous Emissions Monitoring Systems (CEMS)

In certain cases, Rule 1146 requires the installation of a NOx CEMS.

For example, under SCAQMD Rule 1146, a NOx CEMS is required in cases where the rated heat input capacity is >= 40 MMBTU/hr and an annual heat input is >200,000,000,000 BTU/year.

If a CEMS unit is required for your boiler, the system must be permitted on its own, which means that you need to file a separate permit application for the CEMS unit.

2 questions about portable analyzer testing and compliance

1. What happens when a boiler fails a portable analyzer test?

Generally, a facility can correct the problem and retest the boiler within 72 hours.

If, however, the SCAQMD performs its own emissions test and the boiler fails that, it’s an automatic violation of either Rule 1146 or Rule 1146.1.

2. Can a source test serve as one of the required portable analyzer checks?

Based on our experience, we have received guidance that a source test can serve as one of the required portable analyzer checks, but it’s best to verify it with your inspector.

The Most Important Thing we Learned by Helping our Clients Operate a Successful Boiler Program to Comply with SCAQMD Rule 1146 or Rule 1146.1

The key to a good boiler program is maintaining good communication between the environmental staff, boiler mechanic and emissions tester, because without it, problems tend to arise.

What follows is a short list of problems that we’ve observed while helping our clients comply with SCAQMD Rules 1146 and 1146.1:

- The permit requires a source test more frequently than what is specified in the rule

- Operators miss a required portable analyzer testing

- The boiler doesn’t pass a portable analyzer check, and a retest was not conducted within 72 hours

- A portable analyzer test wasn’t scheduled because the operator didn’t know the testing schedule

- The field technicians didn’t notify anyone that the boiler failed the source test

- The field technicians didn’t notify the environmental staff that the boiler failed a recent portable analyzer test

- The required source test wasn’t scheduled in time because no one was tracking the operating hours of the boiler

- The required portable analyzer test wasn’t scheduled in time because no one was tracking the operating hours of the boiler

- The emissions technician didn’t provide the results of the recent portable analyzer test to the environmental staff

Let’s Take This Over to You

Do you know someone who has a boiler that is operating in Southern California?

If so, please share this article with that person so that he or she can know of the common problems that people have when they comply with SCAQMD Rule 1146 or Rule 1146.1.

Also, sign up for the Envera Consulting newsletter so you won’t miss our next article.

No SPAM, just content that guides you through all of the SCAQMD’s air quality rules and regulations that your business needs to address in order to comply.

###

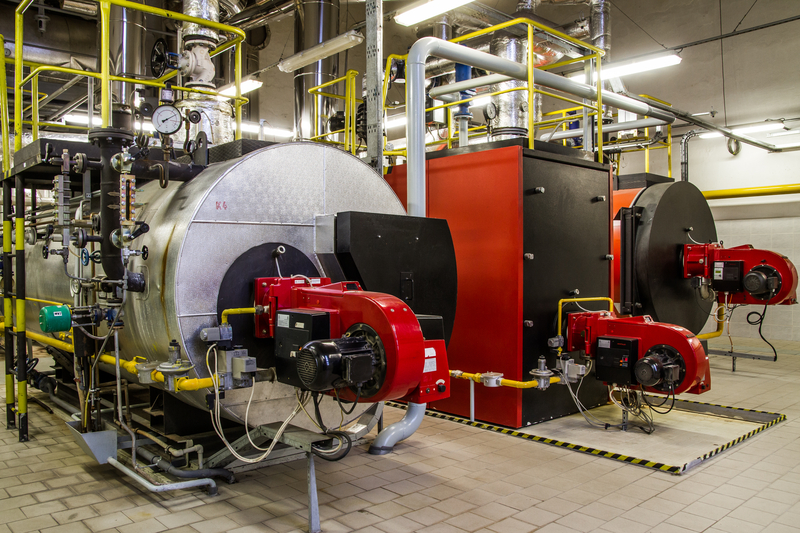

Image Credit: Boilers