The following text is an abridged and edited transcript of the above video.

There’s a common misconception that calculating air emissions is a long and tedious process, with complicated equations. While we have seen cases where calculations can take up several pages and even require a computer program to model the emissions, most of the time, the process can be boiled down to a simple equation.

[00:50] General Formula for Calculating Air Emissions

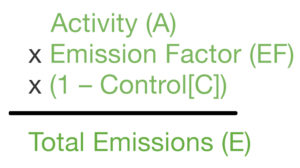

Here’s the general equation for calculating air emissions:

The calculation tells us that the air emissions from any piece of equipment is equal to the activity rate (A) multiplied by the emission factor (EF), multiplied by one minus the control efficiency. If we have all of those components, we can calculate our emission rate for a single piece of equipment.

[01:40] Calculated Emissions (E)

Let’s first talk about E, the emission rate — the value you eventually want to get to. Because the way the equation is set up, E will give you the emissions from one process, or from one piece of equipment. If you have a complex facility with multiple pieces of equipment and multiple processes, you would use this same calculation for each piece of equipment and each process, then add up each to get the emissions for the entire facility. The important thing to remember is that this general equation is for one piece of equipment or one process.

It’s also important to note that the amount and types of pollutants emitted by a specific process or by a specific piece of equipment will vary from equipment to equipment and from process to process. For example, if you have a storage tank with gasoline, then you should only expect to see emissions of organic compounds, since those are the evaporative losses from the gasoline being stored in the tank. On the other hand, if you have a boiler or an engine that combusts fuel, then you should expect to see combustion contaminants that include nitrogen oxide (NOx), sulfur dioxide (SOx), volatile organic compounds (VOCs), carbon monoxide (CO), and particulate matter. As a third example, if you have a flour silo, you shouldn’t see emissions of VOCs because there are no evaporative emissions from that piece of equipment; instead, you would see emissions of particulate.

Lastly, if you had a bulk-loading system loading organic material, you should only expect to see emissions of organic compounds. Again, the amount emitted and the types of pollutants emitted by these processes differ based on equipment and process type.

[04:17] Units of E

The units of E are typically in mass per time, such as pounds per day, pounds per hour, pounds per month, or pounds per year. The unit of E will depend on the duration you’re examining, which is determined by the activity (A). When it comes to permits, the most common units of E we see are pounds per day or pounds per hour. Keep in mind, however, that an annual emission report normally requires you to calculate emission in pounds per year.

[05:09] Activity (A)

Activity (A) is a measure of how active a piece of equipment is, and there are various ways to calculate this component. You can use the amount of material processed, measured as either raw material or the finished product; the elapsed time that a piece of equipment is in operation; or the amount of fuel that’s consumed per unit time. So, if your unit of measurement is one month, then the activity would be how much fuel was consumed by the piece of equipment in one month.

Depending on the piece of equipment, the activity might be presented as a measurement of volume per time. For example, when calculating the annual emissions of a boiler, you need to look at the total amount of fuel consumed by that boiler in a one-year period. On the other hand, if you have an emergency engine like a fire pump or backup generator, it isn’t uncommon to see those activity metrics in terms of duration per time period; for example, fifty hours per year, ten hours per month, etc.

Because data can come in all sorts of units, you need to know how to convert it into something that’s usable, which we’ll get to a few sections down.

[06:12] Units of A

Activity is expressed in units per time period, such as pounds per days or hours per month. Keep in mind that the denominator of the activity will determine the unit measured in the emissions (E).

[07:00] Emission Factor (EF)

The emission factor (EF), which relates the process activity to the amount and type of pollutants emitted, is the part of the equation that can take the most time to develop. The units of an emission factor are always mass per activity unit. Since the activity (A) relates to emissions through the emission factor, you need to be absolutely sure that the units cancel out when doing the math.

Some examples of typical emission factors are:

- pounds of NOx per million cubic feet of natural gas combusted (the million cubic feet of natural gas is the activity unit [A])

- pounds of VOC per kilogram of plasma processed

- pounds of sulfur oxides (SOx) per pound of trash processed

[08:13] Where to Find Emission Factors

How to determine an emission factor is one of the most common questions in calculating an equipment’s emissions. We have an entire video that describes the four ways to determine an emission factor (listed here in order from most accurate to least):

- Do a direct measurement, or source test. In most cases, you’ll have to hire a third party to measure the emissions from your piece of equipment while it’s in operation.

- Look one up. AP42 is an enormous, well-known database of emission factors. You can also visit the websites of local, state, or federal agencies, which often contain databases of emission factors, or refer to material safety data sheets (MSDS), which sometimes include this information. For equipment specification, you can also ask a trade organization.

- Do a mass balance. This method assumes that everything that goes in comes out. For example, when calculating SOx from the combustion of diesel fuel by an engine, we know the SOx in diesel fuel is 0.15 parts per million. Assuming all of that sulfur is converted to SOx, we know how much SOx is being emitted from the stack.

- Do an engineering calculation. This requires you to use your knowledge about a piece of equipment along with generally accepted engineering principles.

Although a source test is usually the most accurate method, it’s also most often the most expensive, while looking up the emission factor tends to cost the least. You have to balance this trade-off between accuracy and cost when selecting the method to determine your emission factor.

Keep in mind that you’ll most likely have to manage the units — and possibly convert them so that they cancel out. For example, if the emission factor comes from a look-up table, the units might be in grams per brake horsepower hour (g/bhp-hr) or pounds per gallon, while a direct measurement will most likely result in a concentration, because the company is measuring the concentration of a pollutant out of the exhaust stack.

[10:32] Control Efficiency (C)

The control efficiency is dependent on whether or not the piece of equipment has a control device, such as a selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR) system, installed. Control devices alter, lower, or control the emissions from a piece of equipment. These values are typically expressed as a percentage, without units.

You can determine whether a control device is installed by inspecting the piece of equipment, asking questions, or reviewing permits and/or equipment specifications. In many cases, you’ll find that the equipment doesn’t have a control device at all. But you should always make sure first, as not factoring it in can greatly increase your emission calculations.

If the equipment does not have a control device, you may have to look at the emission factor and the information that was used to develop the factor to determine if the control efficiency is built into the equipment’s emission factor.

For equipment that does have a control device, you may need to perform a test to determine how much pollution is coming out of the device itself and, thus, its control efficiency. The numerical value of the control efficiency will depend on many factors, such as technology, the type of equipment, meteorological conditions, process, and much more. In addition, there are numerous things that can affect the control efficiency, and the value differs between the pieces of technology used. As an example, an afterburner that controls VOC would have a different control efficiency than an SCR unit for NOx, and a bag and filter house for particulate would differ from a wet scrubber controlling emissions of SOx.

Going back to our general equation, a control factor of 1 can be used if there is either no control or it is built into the emission factor. But before you do that, you need to understand your emission factor, the history of that emission factor, and all of the details that went into deriving it.

[12:55] The Importance of Units When Calculating Emissions

The last step I want to show you is how the units work. Typically, the units for the control are in percentages, meaning there aren’t any units associated with the control value. The units of E are in terms of mass per time, the units of A are expressed in activity units per time, and the EF is expressed in terms of mass per activity unit. When you do the math, you can see that activity cancels with activity unit [see video for diagram]; this is unit-less and therefore you have mass per time, the unit of E.

This is important because when you start to use more elaborate ways to derive an emission factor, you’ll want to make sure that your units are correct. More importantly, you’ll want to be sure that your activity and the emission factor are in the right units so that everything cancels out. For example, if you’re using pounds for one component, you shouldn’t be using kilograms for another. You don’t want to be multiplying a million cubic feet by pounds and getting some weird, artificially high number, which results in you paying tons of fees on your annual emission report.

Hopefully we’ve demystified how to calculate air emissions, and we’ve hopefully equipped you with the knowledge to prepare your annual emission report, which is coming up in just a couple of months. If not, contact us and we’ll guide you through the process.